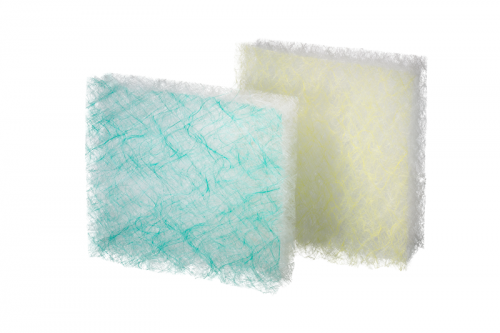

Air-conditioning and ventilation filters

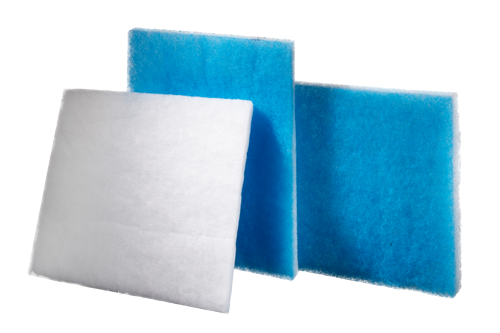

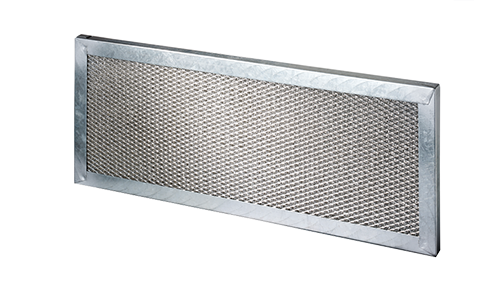

Antistatic or biostatic versions are also available. Our product range includes coarse filters, medium filters and fine dust filters.

Air-conditioning and ventilation filters at ELSÄSSER

Our extensive air-conditioning and ventilation filter range includes the filter classes specified in the old (yet still-often-mentioned) EN 779 standard: G2, G3, G4, M5, M6, F7, F8, F9, and those specified in the new ISO 16890 standard: coarse, ePM10, ePM2.5, ePM1, and EN 1822-1 for E10, as well as U17 for HEPA filters. All of these products are characterized by impressive levels of safety and quality as well as environmentally friendly materials and short installation times. Experience our excellent service and take advantage of our products’ outstanding price / performance ratio.

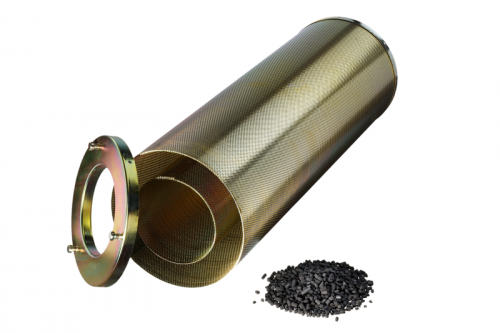

Various air-conditioning and ventilation filters containing activated carbon are available for adsorption to remove unwanted substances from the air. We are also your competent partner for customized solutions in this product area. In addition to air-conditioning and ventilation technology, we serve various sectors with this filter range, such as industry, energy, general construction, and room ventilation technology.

Available upon request with EuroVent certification.

Where are these filters used?

Air filters are installed in all ventilation systems. And our product range covers each and every one of them, both in public and commercial buildings. Our filters are used wherever ventilation systems ensure a pleasant indoor climate and protect people and their health – whether in the field of ventilation, heating or air-conditioning technology.Types of air-conditioning and ventilation filters

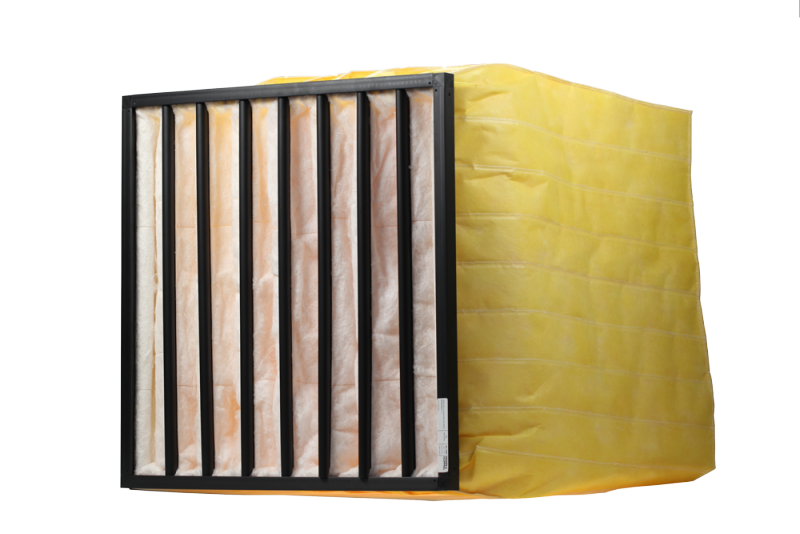

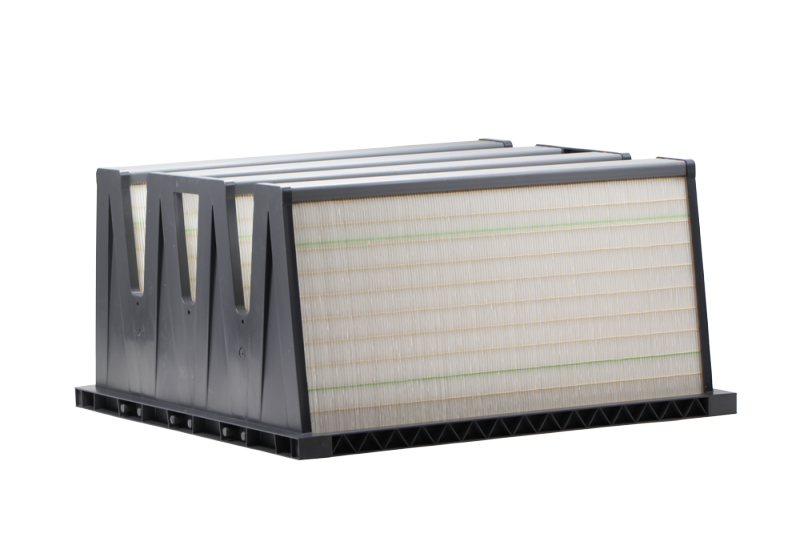

The most common and widely used products are traditional pocket filters with plastic or metal frames, as well as cassette and compact filters. From the ground up, we provide inherently rigid pocket filters that offer uniform, optimum flow rates at low differential pressures.For more challenging requirements, we can supply pocket filters with special spacers and V-shaped designs to further reduce the pressure losses in the system. In addition, multilayered filter media are used to maximize the dirt pick-up and dust-holding capacity. Modern nanomaterials offer significant energy savings and thus cost reductions compared to the traditional filter materials of recent decades.

Advantages and mode of operation

The purpose of every filter is to separate particles to the degree specified in the respective standards, which is referred to as the “retention rate”.Pocket filters are usually fabricated by means of sewing or welding, depending on the filter material (synthetic fiber or glass fiber). Ensuring the correct installation position of a pocket filter – with the pockets always upright – is a prerequisite for trouble-free operation with minimal pressure loss. For all filter types, such as bag, panel or compact filters, careful attention must be paid to the filter’s orientation and installation location. The markings indicating the air flow direction must be observed. In addition, it is important to regularly check the unit for damage if the gaskets have been used more than once. This is the only way to be sure that the filter will work properly.

The mode of operation of a filter, regardless of its design, is always the same. Particle separation takes place between the upstream side (= dirty side) and the clean side. Depending on the application, surface or depth filters may be used. Using the traditional pocket filter as an example, the air to be cleaned passes through the pockets from the inside to the outside. Depending on the plant or application, it usually makes sense to filter the air via multiple filter stages. The first filter stage, the pre-filter, traps the coarse dirt and thus protects the highly effective fine filter from excessive dust loads, thereby extending its service life.